There is nothing more essential to patient welfare than sterilization.

One component of St. Lawrence Dentistry’s sterility protocols is the use of chemical indicators. They are an accurate, powerful visible signal to health care professionals which confirms profound sterilization. Chemical indicators are a critical element in the sterilization of dental tools. When used in combination with spore testing and physical monitoring, they ensure St. Lawrence Dentistry maintains high infection control standards.

All dental instrument sterilization in Canada has three kinds of monitoring: mechanical, biological, and chemical.

- Mechanical tracking symbolizes that “autoclaves” perform at the right temperature, for the correct time, at the proven pressure. This data is recorded for every “load” of tools sterilized.

- A biological indicator contains a “carrier material” containing bacterial spores with a defined resistance to the sterilization process. The indicator undergoes the sterilization process and then is incubated under established growth conditions to discover whether any spores endured the process.

- Chemical indicators are indispensable since they prove that instruments have gone through the sterilization between biological monitoring. Chemical indicators use compounds that experience either a physical or chemical transformation visible to the human sight after exposure to predetermined critical parameters like temperature and time. Our article today will focus on these.

Chemical indicators

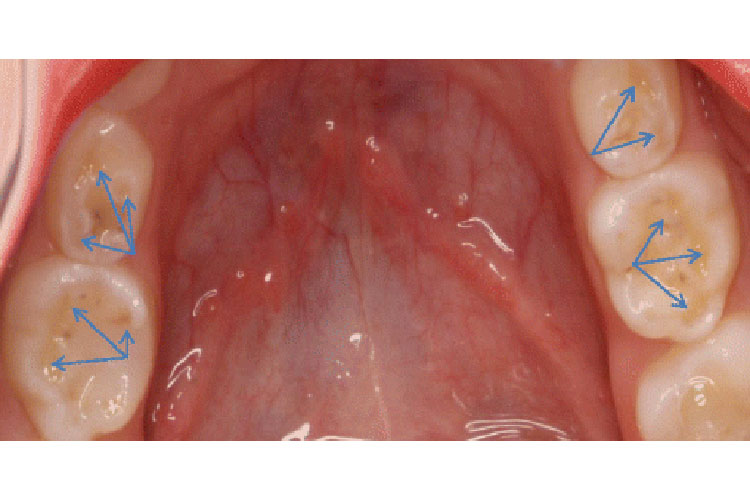

St. Lawrence Dentistry’s instrument packaging has two types of chemical indicators: external and internal. Indicators on the packaging surface confirm instrument exposure to heat. Those inside indicate whether the sterilizing agent (steam) penetrated the packaging to reach the instruments. There is a color change on the indicators when the steam or chemicals attain precise parameters, establishing the efficacy of the sterilization process. We also use “dual indicators”, which evaluate both inside and outside the packaging.

How do we use them?

Our Mississauga dental clinic uses several types (previously referred to as “classes”) of chemical indicators. Type 1 indicators, or “process indicators”, are used outside the packaging to distinguish between processed and unprocessed instruments. A specific test indicator (type 2) assesses performance and concludes if the autoclave correctly completed air extraction in a pre-vacuum sterilizer. The most popular test in this category is the Bowie-Dicks test. Type 3 indicators, such as single-variable indicators, gauge temperature or time, and test exposure in specific locations. Type 4, or multivariable indicators, can react to more than one parameter designated by the builder. Finally, type 5 and type 6 indicators are used inside packaging and can respond to all essential parameters in sterilization. The parameters observed throughout the sterilization process include time, temperature, and steam presence. By ascertaining the levels of each of these assessable factors, chemical indicators give direction as to whether the sterilization was complete.

Why do we use them?

Chemical indicators are a crucial part of ensuring our instruments have experienced the sterilization process completely. In the most simplistic terms, chemical indicators assure the protection of our valued Mississauga dental patients. They use delicate, color-changing compounds to register whether physical circumstances like time, pressure, and temperature have reached the needed amounts required to sterilize the tools. They are not proof of successful sterilization but rather a discovery process that can show procedural errors or machinery faults. Spore tests are the only accurate way to confirm that the process is successful- which our Mississauga dental clinic also uses.

Our dental clinic has rigorous protocols to ensure our instruments are always 100% sterile. Sterilization failures could happen due to inadequate packaging, overloading an autoclave, or various other shortcomings of the autoclave itself. Although chemical indicators are insufficient in and of themselves to ascertain whether sterilization has happened, when utilized along with physical monitors and daily spore testing, they can be a vital tool for quality assurance.

When do we use them?

The use of chemical indicators varies on the sterilization method and the instruments. However, we always use a chemical indicator when sterilizing instruments. Chemical indicators are used in combination with biological indicators to monitor the precise functioning of sterilization cycles, and therefore, are used in every sterilization cycle. Patient protection is of the utmost importance to Dr. Hawryluk. Rest assured, St. Lawrence Dentistry rigorously follows all sterilization processes and protocols. Our dental clinic is in Mississauga by Lake Ontario. We would be happy to serve you!

References:

Rani L, Pradeep. Sterilization protocols in dentistry—A review. J Pharm Sci Res. 2016;8(6):558-564. Accessed December 15, 2020.

Sterilization: Monitoring. CDC: Accessed December 15, 2020. (https://www.cdc.gov/oralhealth/infectioncontrol/faqs/monitoring.html)

Huber MA. Biological indicators [continuing education course]. DentalCare.com. Accessed December 15, 2020. (https://www.dentalcare.com/en-us/professional-education/ce-courses/ce474/biological-indicators)

OSAP: the safest dental visit. Accessed December 17, 2020. (https://www.osap.org)

Galloro G. Setting the record straight on infection prevention and control. The facts about steam, chemical indicators. CDHO. Accessed December 15, 2020.

6 ISO types of chemical indicators for steam sterilization. Steris Life Sciences. Accessed December 15, 2020. (https://www.sterislifesciences.com/resources/documents/article-reprints/chemical-indicators-for-steam-sterilization)

https://www.rdhmag.com/infection-control/article/14196612/chemical-indicators-a-must-for-proper-sterilization

- St. Lawrence Dentistry Looks Forward To St. Patrick’s Day! - March 12, 2025

- Understanding Dental X-Rays and Radiation: What You Should Know - January 13, 2025

- Happy New Year from St. Lawrence Dentistry! - December 30, 2024